VFD Systems & Integration

Helix is a leading provider of advanced drive solutions, offering a comprehensive range of stand-alone and integrated systems. Since the inception of AC drive technology, our team has remained at the forefront of innovation, with a strong focus on HVAC applications. Today, Helix drives power large-scale AHU systems, cooling towers, pumps, conveyor systems, and more—delivering reliability and performance across diverse environments

Overview

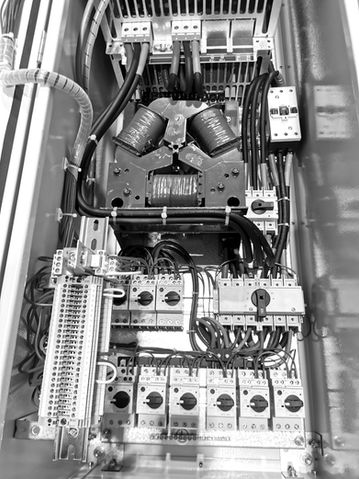

Helix offers VFD solutions that go far beyond simply supplying components in a box. Our assemblies are engineered for optimal performance, with wiring and component layouts designed to minimize interference while ensuring easy access to power and control termination points.

Each layout is carefully planned to provide proper ventilation and airflow for high-temperature components, keeping the entire assembly within manufacturer and CSA guidelines. Every Helix VFD assembly undergoes full-load testing and is pre-programmed prior to delivery, making on-site start-up quick and efficient. When motor data is provided before factory testing, the programming is finalized so no parameter adjustments are needed during commissioning—just voltage verification and confirmation of proper field wiring.

Why Helix Drives?

Helix is a leading supplier of AC motor control technology and automation products, continually advancing our line of variable frequency drives for heating, ventilation, air conditioning, and refrigeration applications. Our HVAC VFD portfolio is engineered with the features and functionality essential for modern HVAC systems, delivering the same reliability, durability, and energy-efficient performance that define our industry-leading solutions. To ensure long-term protection, all control boards are conformal coated as standard, safeguarding against corrosion caused by common atmospheric chemicals.

The Helix series of VFDs is engineered and manufactured to meet strict specifications, ensuring protection against radio frequency interference (RFI), electromagnetic interference (EMI), harmonics, and potential motor issues. Each unit incorporates standard harmonic filtering that reduces harmonic current by more than 50% compared to VFDs without input line filtering.

BUILT AS PER UL, CSA & NEMA STANDARDS

RUGGED FAULT TOLERAN MODULAR CONSTRUCTION

SERVICE ACCESSIBILITY WITH ONBOARD DOCUMENTATION

ADVANCED DIAGNOSTICS WITH TEMPERATURE & THERMAL PROTECTION

ISOLATED MAIN BUS & MOTOR CABLE TERMINATION SECTION

AIR COOLED IP 42 DESIGN

Helix Drive Options

Enclosure Options

Standard Design

-

NEMA-1, NEMA 12 Ventilated, NEMA 3R Ventilated and NEMA 4 Wall- Mount, Free-Standing or MCC Mounted

-

Free-Cooling and Forced Air Cooling

-

Galvanized Interior Mounting Pan

-

Powder Coat Paint Finish: Light Grey (Standard),

*Alternate paint finish available upon request.*

-

208/220/230 Volt, 1 or 3 Phase Input, 50/60 Hz

-

460/480 Volt, 1 or 3 Phase Input, 50/60 Hz

-

575/600 Volt, 1 or 3 Phase Input, 50/60 Hz

-

Three Contactor Bypass

-

VFD-OFF-Bypass Selector Switch

-

VFD Run Pilot Lamp (RED)

-

Bypass Run Pilot Lamp (RED)

-

Run/Stop Control Relay

-

Motor Overload Relay

-

NEMA Enclosure Options (1, 12, 3R and 4)

-

Fused Disconnect Switch

-

Fused 120 VAC Control Power

-

Input Reactor or Filter

-

dV/dt Filter

-

Customer Control Terminal Blocks

-

Chassis Mounted VFD

-

English Text Keypad Mounted on Cabinet Door

-

Exhaust Air Fans Cooling as Required for Heat Dissipation

-

Harmonic Filter

-

Transient Surge Protection for transient spikes up to 3000 VAC and 250 Joules

-

Input Isolation Contactor

-

VFD Output Contactor

-

Bypass Contactor with RVS Starter

-

Motor Starter Protection Relays (MSP) (for multi-motor applications)

-

Input Power Distribution Block for Top or Bottom Entry

-

Motor Power Distribution Block for Top or Bottom Entry

Voltage Options

Bypass Options

Additional Options

Helix is vendor neutral, and open to customization. This allows Helix VFD solutions to meet the requirements of nearly all customer projects and scope of works.

VFD Applications

-

Airports

-

Hospitals

-

Shopping Malls

-

Entertainment and Sports Facilities

-

Schools and Universities

-

Hotels and Restaurants

-

Municipal and Commercial Buildings

-

Chillers and Compressors

-

Cooling Towers

-

Boiler Circulation Pumps

-

Chill Water Circulation Pumps

-

Exhaust Fans

-

Clean Room Air Handling

-

Tunnel Ventilation

VFD Power Schematic With Multiple Options